Confined Space Inspections

Regardless of the purpose for an inspection in a confined space, one constant holds true, confined space inspections require more planning, specialized skills, equipment, labor and time to access or dismantle the system. Depending on the nature and location of the inspection, a confined space could also pose significant risks.

First, there are the physical challenges. Gaining access, limited mobility, ease of using equipment within the space, communication, and regulating the body temperature of inspectors create an environment of constant and significant risks throughout the inspection.

In addition to these physical challenges, there is also the risk of the unknown. Inspectors operating in a confined space could be exposed to several health hazards ranging from site contamination to hazardous gasses, chemicals, inadequate oxygen, fire, or explosion.

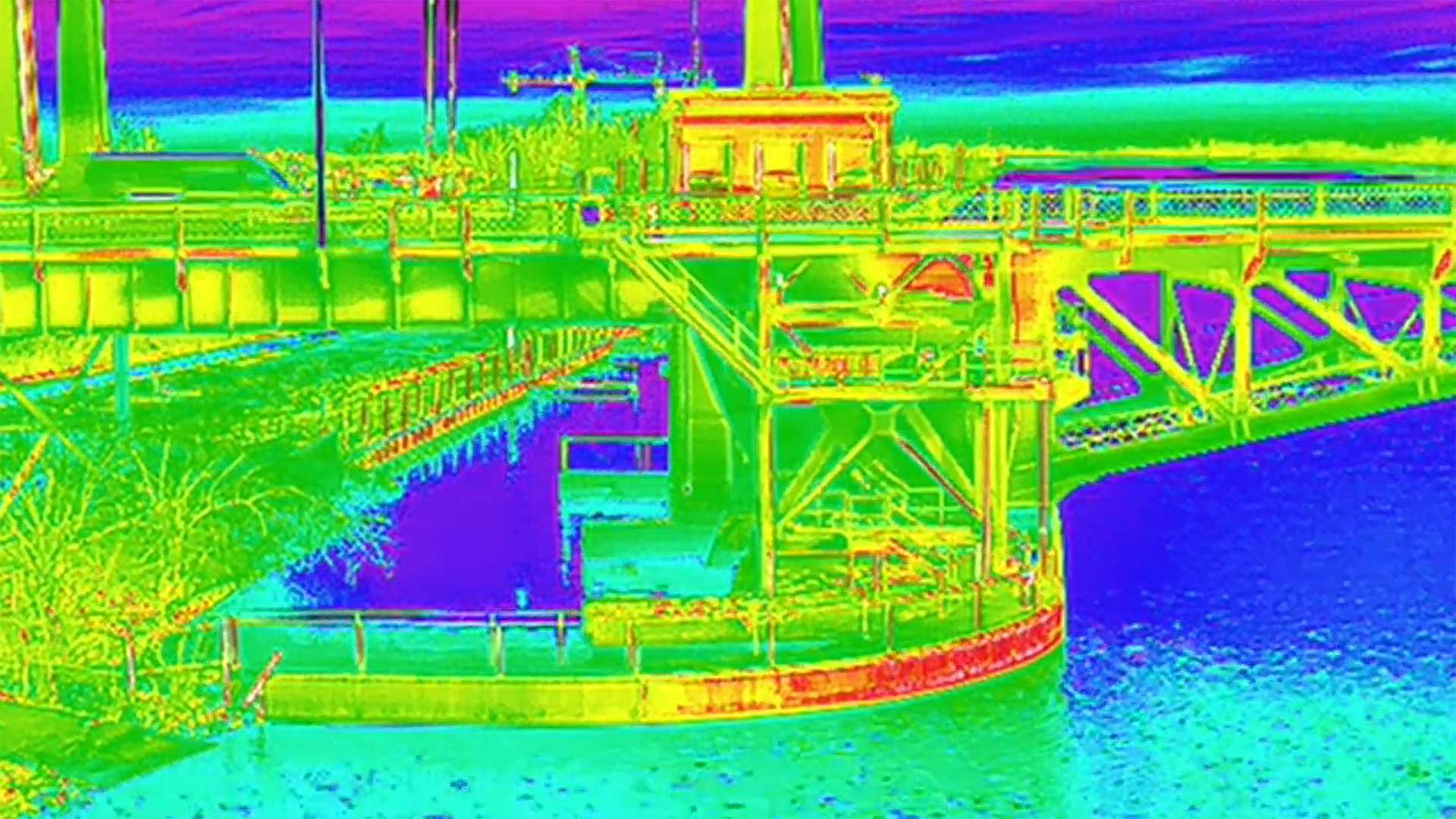

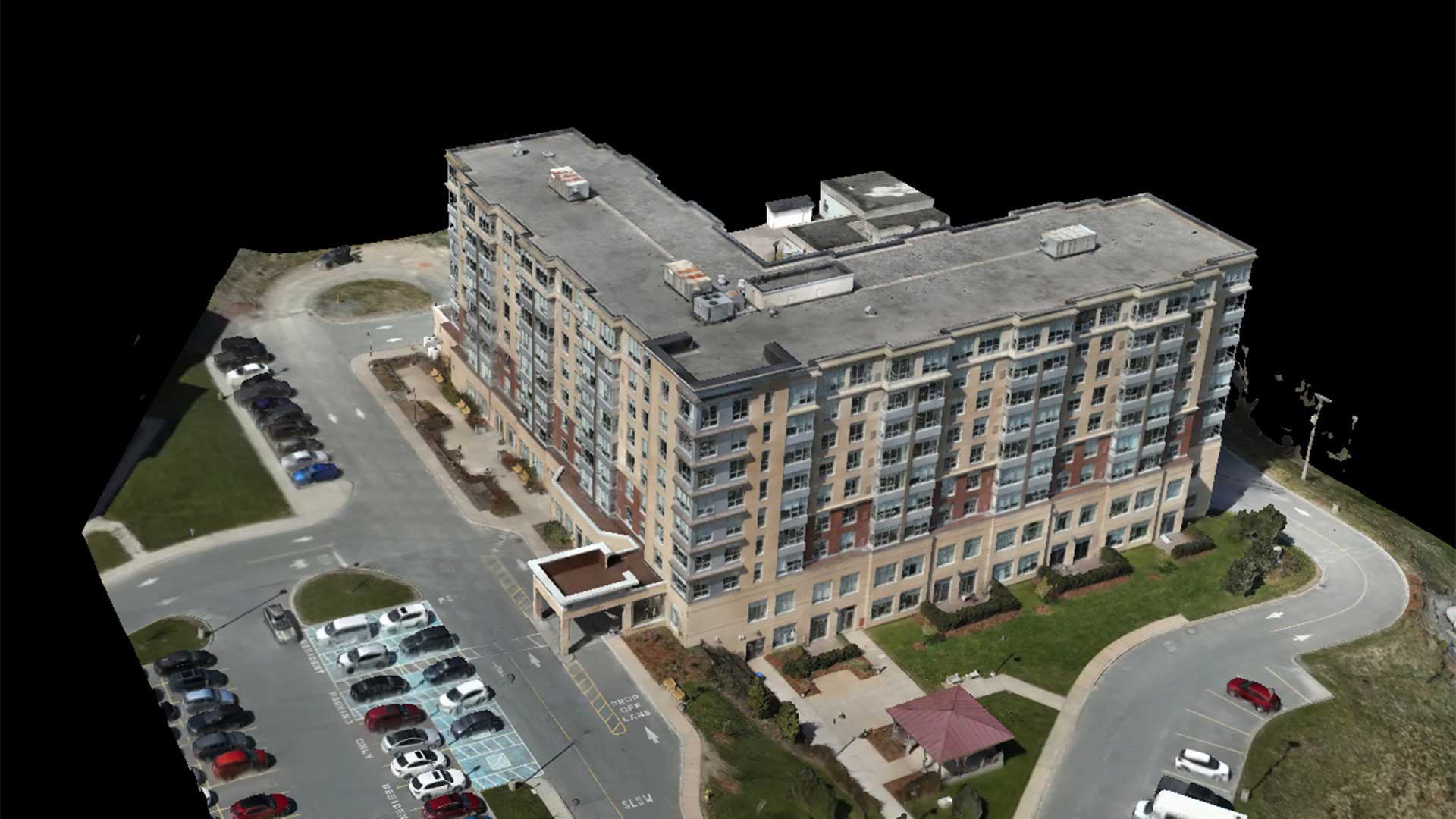

While a confined space drone may not be suitable to replace all aspects of the confined space environment, it can help provide preliminary visual inspections more quickly, at a lower cost, and with significantly lower risk. However, using drones for this type of work requires a specialized drone, a means to control the drone beyond visual line of sight, the skill to operate the drone without traditional self-leveling or GPS support, and, in some cases, a certification to undertake the work.

By working with Altomaxx, you gain a partner that has the equipment, expertise, and experience to safely and successfully support your confined space program. As a Lloyd's Register Approved Service Supplier and RPAS inspection company with DNV-GL certification, Altomaxx utilizes Remote Inspection Techniques (RIT) for close-up surveys of ship structures and mobile offshore units in accordance with Class Programme DNVGL-CP-0484.

Our unmanned aerial vehicle operations meet all industry-specific policies and procedures required to conduct confined space inspections and provide you with reduced inspection costs, reduced inspection time, better asset management, and improved safety – all while providing a comprehensive data collection platform.